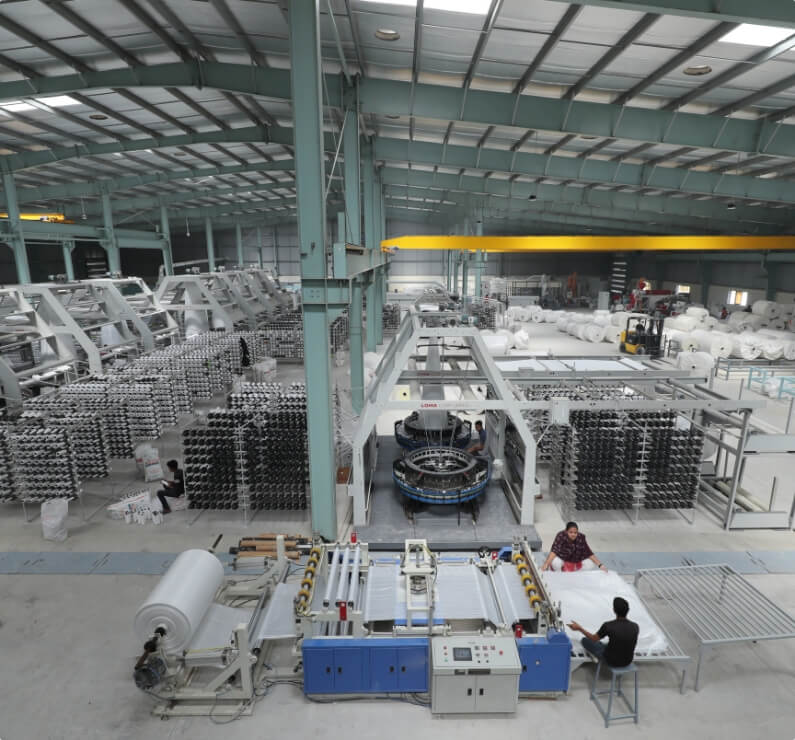

With rapid changes in warehousing management, speed, sustainability, and adaptability are now the keys factor now. There are lots of tools and techniques at the disposal of the manufacturers, yet bulk bags are unique and they can revolutionize the way warehouses operate. These big, powerful containers are very useful. They can make storage more effective and smooth the running of processes. We examine the top five creative ways the flexibility and potential of bulk bags can be used in a warehouse in the following article.

1. Optimized Storage and Organization:

Warehouses always try to optimize the use of their storage space without sacrificing the easy access to goods. Space-saving mechanisms in traditional storage methods might not all be effective, which results in money and time being wasted. A bulk bag is a revolutionary option as it is a scalable option for solving the storage problems in an easy way.

a. Vertical Space Utilization:

Bulk bags are effective in this regard because they adequately occupy the unused vertical space in the warehouse, which is one of their most important advantages. The warehouses can use the spaces above the stacks by stacking bulk bags vertically. With the smart stacking, every available space is used, and at the same time, the process of handling the items is facilitated.

b. Enhanced Organization:

Labeling the bags should be simple and color-coded systems make bulk bag storage even more orderly. Through implementation of standard labeling guidelines and color schemes, warehouses can facilitate keeping track of products and helping them find what they are looking for. The novel approach also reduces the time the worker spends in looking for things, that makes the entire process more productive.

c. Dynamic Storage Solutions:

Bulk bags are a flexible way to store things that can be used as the warehouse’s needs change. Because they are made of separate modules, storage layouts can be easily changed. This lets warehouses adapt to changes in inventory number or product mix. Whether it’s because of changes in the seasons or sudden changes in demand, bulk bags give you the freedom to make the best use of your store space.

2. Efficient Material Handling and Transportation:

Moving things around easily in the warehouse is important for keeping things running smoothly. There are often problems with handling and transporting traditional packing methods, which causes delays and waste. Using bulk bags is a simple way to deal with these problems head-on.

a. Robust Construction:

There is a lot of sturdiness in bulk bags, which makes them perfect for transporting different things safely. Their sturdy design keeps the goods safe while being handled and shipped, lowering the chance of damage or spoilage. Bulk bags are a safe way to keep things together that can handle the rough conditions of the supply chain. They can be used for grains, aggregates, or chemical powders.

b. Flexible Handling Options:

Unlike rigid containers or palletized goods, bulk bags give you more choices for how to handle them. Forklifts, pallet jacks, or overhead cranes can easily move them, based on the equipment and infrastructure of the warehouse. This versatility speeds up the process of moving things, which means less manual labor and a lower chance of injury.

c. Streamlined Logistics:

Warehouses can improve logistics and lower overall shipping costs by using bulk bags for all of their packages. The consistent sizes of bulk bags make it easier to load them onto cars or shipping containers and put them on pallets. Also, bulk bags can be stacked higher than regular packing, which makes better use of storage space and cuts down on the number of trips needed to deliver orders.

3. Customized Packaging Solutions:

Customization is essential in customer preferences meeting with the diverse and competitive market now due to the high level of competition. Bulk bags are a changeable way to package items because they can be adjusted to fit different products. This renders the handbags more useful and adds to the appeal of the brand.

a. Tailored Specifications:

There is a wide range of customization options available in terms of the size, material and style of bulk bags. These bulk bags can be tailored to fit specific goods such as weight capacity, moisture barrier, or UV protection. The fact that these products can be personalized assures that they are packed safely and remain in good shape all through the supply chain.

b. Branding and Marketing:

In addition to being functional, large backpacks can also be branded and marketed. Warehouses can use custom printing to print logos, products information or advertisement messages directly on the bags. This branding does not only make the product more visible, but as well helps people to recall the brand as it runs through the process of promotions.

c. Sustainable Packaging Alternatives:

As the environment concern is perpetually growing, warehouses are on the lookout for more eco-friendly methods to package their items. Switching to bulk bags is one of the solutions to decrease waste and protect the land. Repeat use and recycling of bulk bags are beneficial for the circular economy model. A firm can be ecologically friendly and promote its image by using bulk bags for packing.

4. Environmental Sustainability:

Securing environmental safety has become a primary objective for enterprises in all fields. Warehouses are where a lot of this happens, and the process also influences the environment in an indirect way. As a sustainable packaging alternative that addresses both the environment and the economy, bulk bags rank first.

a. Reusability and Durability:

Bulk bags are made to be reused, so they don’t need to be replaced often. Their longevity makes them reliable, and their low garbage output reduces packaging waste. Warehouses can contribute significantly to the solution and save money in the long run by buying reusable bulk bags.

b. Resource Efficiency:

The fact that bulk bags are light helps the supply line use resources more efficiently. To make bulk bags, less raw materials and energy are needed than to make standard packaging materials like wooden crates or metal drums. This use of resources more efficiently not only has a smaller effect on the environment, but it also cuts down on fuel use and transporting costs, making things even more sustainable.

c. Closed-Loop Systems:

Warehouses can adopt the closed-loop method whereby reuse and recycling are encouraged, as this ensures the highest environmental benefits possible from bulk bags. Once the bulk bag has been used-up, it can be retrieved, washed and reused. Bags which are not recyclable can be used for other purposes. The warehouses can become custodians of a circular economy by applying the closed-loop methods to minimize the amount of waste produced by them.

5. Facilitating Bulk Material Handling:

As they move, store, and handle bulk goods, warehouses have to deal with some unique problems. There are many ways to use bulk bags, and they make managing bulk goods easier. This improves working efficiency and reduces the complexity of logistics.

a. Containment and Dispensing:

Bulk bags are a way to keep things contained, which makes it easier to move and use large materials like grains, aggregates, and powders. Their built-in outlet spouts allow for controlled dispensing, which cuts down on waste and spills during transfer operations. Bulk bags can also have liners or coatings added to them to keep the goods safe from moisture, contamination, or breakdown. This keeps the quality of the product safe throughout the supply chain.

b. Segregation and Segmentation:

In shops that store a lot of different kinds of goods, bulk bags can be used to sort and divide bulk materials into groups based on their specific needs or traits. Warehouses can keep their goods clean and stop cross-contamination by giving separate bulk bags to different types or grades of products. This strategic segmentation not only improves the quality of the products, but it also makes it easier to keep track of and handle inventory.

c. Modular Storage Solutions:

Bulk bags are a flexible choice of storage which can be varied to meet the warehouse needs and the constrains of the space. Their setup allows the warehouses to change the way storage is configured, which in turn helps them to use space more efficiently by improving their workflow. Bulk bags can be deployed in multiple ways to achieve different storage options. They can be stacked, put on racks, or just left on the floor.

conclusion:

The way things are transported, packaged and stored has entirely shifted with the introduction of bulk bags. Warehousing operations benefit from the versatility of bulk bags in various aspects, including optimizing storage space, reducing the negative impact of the environment, and transporting heavy amounts of materials. Warehouses can be more effective by bringing down costs, meeting the changing needs of different industries, and through the creative potential of bulk bags. Leverage the power of bulk bags to automate your warehouse and elevate your operational efficiency to the next level.

Auzzie Bulk Bags is a leader in making warehouses more efficient. With their high-quality bulk bags, companies can change the way they store, move, and care for the environment. Auzzie Bulk Bags is your trusted partner in driving innovation and success in warehouse management. They offer unmatched efficiency and environmental responsibility.